But why use ModCrete AAC Blox?

ModCrete AAC Blox are the best the industry has to offer and is equipped with a lot of benefits over the conventional clay bricks.

Benefits

High Strength

High pressure steam curing autoclaving process gives AAC unmatched strength to weight ratio, which far exceeds the Indian Building code requirements

Light Weight and Seismic Resistant

AAC blocks have a density range of 451 kg/cum to 750 kg/cum. This results in total cost savings as well as a faster construction period. Light Weight blocks reduce mass of the structure, thus reducing impact of an earthquake on the building. Non combustible nature of blocks provides and advantage against fires, which commonly accompany an earthquake.

Cost Effective

Being lightweight, AAC drastically reduces the dead weight of building, resulting into reduction in steel (up to 20%) and cement (up to 25%) structural cost saving. Lighter product reduces transport costs as well being 15 times the size of a clay brick, AAC wall construction involves 1/15 of joints, thus an overall mortar saving up to 66%

Sound Proof

AAC walls have an excellent sound transmission class (STC) rating of 44. Which results to virtually soundproof interiors, which in turn provides Excellent Acoustic Performance.

Superior Durability

AAC blocks are highly durable and can bear adverse weather conditions. Furthermore, they are earthquake resistant. Being ultra-light weight helps AAC be long lasting. Regions of high seismic activity like Japan exclusively use AAC. As it has proven to withstand wind loads of category 5 tropical storms.

Fire Resistant

Best in class fire rating of 4 hours. The melting point of AAC is over 1600 celcius. more than twice the typical temperature in a building fire of 650 celcius.

Accurate Dimension

Its automatic manufacturing process gives AAC an exceptional dimensional accuracy & smooth surface, eliminating need of three-coat plaster walls and allowing for a final 6mm skim coat (putty/pop). Our AAC provides greater Design Versatility & Flexibility.

Thermal Insulation

It has highest thermal rating in the industry: R30! Thus, it provides well insulated interiors, keeping out warm air in summer and cold air in winters. AAC reduces Air conditioning cost upto 30%.

Workability

AAC blocks can be sawed, drilled, just like wood and hence they prove to be one of the most easy to use construction materials’. It facilitates easier fitting of plumbing, electrical and also wall

fittings.

Eco Friendly

AAC is 100% Green Building Material & is a walling material of choice in LEED certified buildings. AAC is most energy & resource efficient in the sense that it uses least amount of energy & material per m3 of product. Unlike brick manufacturing process which uses previous top-layer agricultural soil, AAC uses FlyAsh (65% of its weight).

Termite & Insect Resistant

Solid wall construction and finishes which bond to the wall have no cavities for insects, termites or rodents to dwell in. This also eliminates entry points. Termites and ants do not eat or nest in AAC. Cannot be penetrated by termites or insects. Reduces need for pest control. Offers maximum protection against damage.

Faster Construction

AAC Blocks helps reduce the construction time by upto 20%. Different sizes of blocks help reduce the number of joints in wall masonry. Easy to install. It sets and hardens very quickly. Lighter blocks make construction easier and faster.

Endless Savings

Increase in Carpet Area

Easy piping and cabling

Design Flexibility

Saving in Steel

Saving in Mortar

Good Sound Insulation

Rapid construction

Good Thermal Insulation

AAC Blocks v/s Clay Bricks

| Parameter | AAC Block | Clay Brick |

| Structural Cost | Steel saving upto 20% | No such saving |

| Cement Mortar for Plaster & Masonry | Requires less due to flat even surfaces & less number of joints | Requires more due to irregular surfaces & more joints |

| Breakage and Utilisation | Negligible breakage almost 100% utilisation is possible | Average 10 to 12% breakage, so 100% utilisation not possible |

| Labour Output | Approximately double of conventional brick | Comparatively slow |

| Quality | Uniform and consistent | Normally varies |

| Efflorescence | No such chance which improves the durability of wall along with plaster & paint in a long run | More chances are there |

| Fitting & Chasing | All kind of fitting & chasing possible as per ISO:1905 | All kind of fitting/chasing possible |

| Carpet Area | More due to less thickness of walling material | Comparitively low |

| Storage | Readily available at any time & any season in a short notice so no storage required | Particularly in monsoon, stock at site is compulsory which block large working places |

| Maintenace | Less due to its superior finish | Comparitively high |

| Soil Consumption | Zero soil consumption. Primary raw materials for AAC blocks is fly ash. This fly ash is ndustrial waste generated by coal based thermal power plants | One sq. ft of carpet area with clay brick walling will consume 25.5 kg of top soil |

| Fuel Consumption | One sq. ft of carpet area with AAC blocks will consume 1 kg of pet coke with controlled bricks emission | One sq. ft of carpet area with clay brick will consume 8 kg of coal without any contrl on emissions |

| CO2 Emission | One sq. ft of carpet area will emit 2.2kg of CO2 | One sq. ft of carpet area will emit 17.6 kg of CO2 |

| Labour | Organised sector with proper HR practices | Unorganised sector with rampant use of child labour |

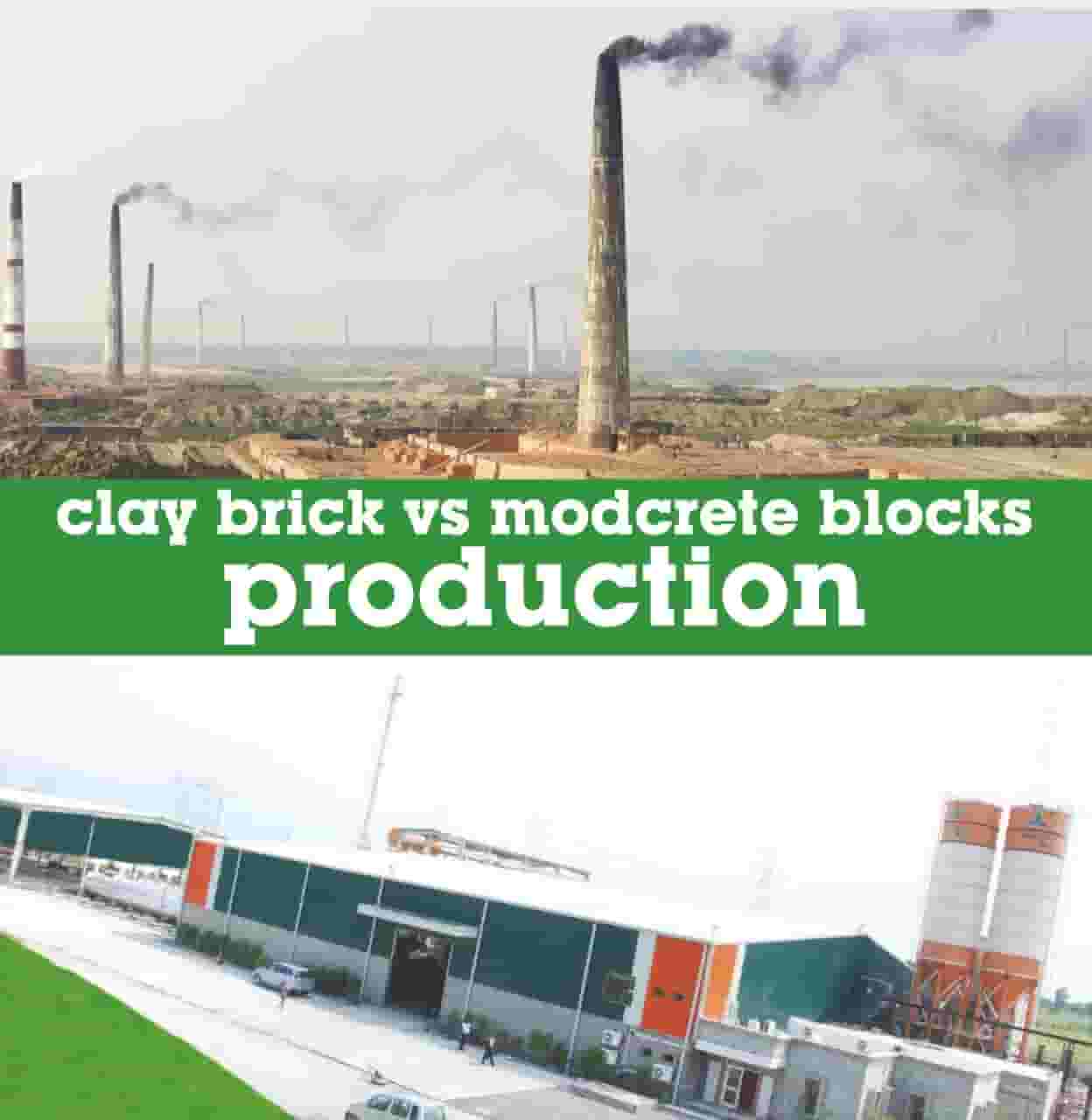

| Production Facility | State-of-the-art factory facility | Unhealthy working conditions due to toxic gases |

| Tax Contribution | Contributes to government taxes in form of Central Excise. VAT and Octroi | Lesser contribution to government exchequer in terms of Taxes and Excise |

| Size | 600/625mm x 200/240mm x 100-300mm | 225mm x 100mm x 65mm |

| Variation in Size | 1.5mm(+/-) | 5mm(+/-) |

| Compressive Strength | 3-5 N/mm2 ( can be higher as per requirement) (can also be upto 10 N/mm2) | 2.5-7.5 N/mm2 |

| Dry Density | 550-700 kg/m3 | 1800 kg/m3 |

| Fire Resistance (8" wall) | Upto 7 hours | Upto 2 hours |

| Cost Benefit | Reduction in dead weight leading to saving in steel, plaster and concrete | None |

| Energy Saving | Approximately 30% fro heating and cooling | None |

| Raw Material | Fly ash, Sand, Cement, POP, Gypsum & Aluminium | Valuable Top Soil and Coal |

| Construction Speed | Rapid construction | Slow construction |

| Breakage | Very less breakage | About 20-25% |

| Heat Insulation | Very good insulation | Poor insulation in comparision to AAC |

Versatile Uses

Hospital

Hospital

Cinema

Cinema

Mall

Mall

Single and Multi Housing

Single and Multi Housing

Schools & Universities

Schools & Universities

Boundary Wall

Boundary Wall

Commerical Buildings

Commercial Buildings

Industrial Buildings

Industrial Buildings

Roof Installation

Roof Installation

Hilly Construction

Hilly Construction

Fire Resistant Solutions

Fire Resistant Solutions

Individual Housing

Individual Housing

Environment

Save Agricultural Soil

ModCrete AAC blocks use 65 to 70% of fly ash, wastage generated from thermal power plant. It does not required clay so no damage of agricultural land and soil.

Save Air Purity

Fly ash wastage is from thermal power plant mixes with environment and increase pollution, because of its use in ModCrete AAC blocks it helps to reduce the pollution.

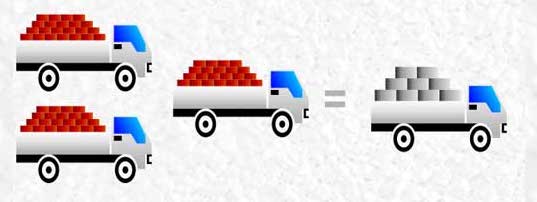

Save Transportation Fuel

ModCrete AAC block are 3 times lighter than clay bricks and 4 times lighter than concrete blocks, so more number of blocks are transported in same vehicle which save fuel for transportation compared to clay bricks / Concrete blocks.

Green Building Certificates

Zero Pollution Production

AAC Block is a zero emissions and discharge industry, and is classified as a White Category industry. The production process itself requires at least 30% less energy compared to clay brick manufacturing and hence contributes directly to better carbon emission foot prints.

Less Water Requirement

As use of thin bed mortar does not require water curing and is cured naturally, the water consumption of installing AAC Blocks is significantly reduced. ModBond & ModPlast doesn’t need more than 24 hours of curing time, the water requirement is substantially reduced.